This was a trash find donated to me so no worries about messing it up. It lead a rough life apparently, and died young judging by the varnish and nice frets.

Here I am trying to cope with a coping saw but on a Fender instead of on a coping, wtf that is.

It was very well built, thanks, China, and my hands will be sore manana. Even finally detached, my sawing and bashing work were just starting with all that bracing. It took a lot to kill something this stout.

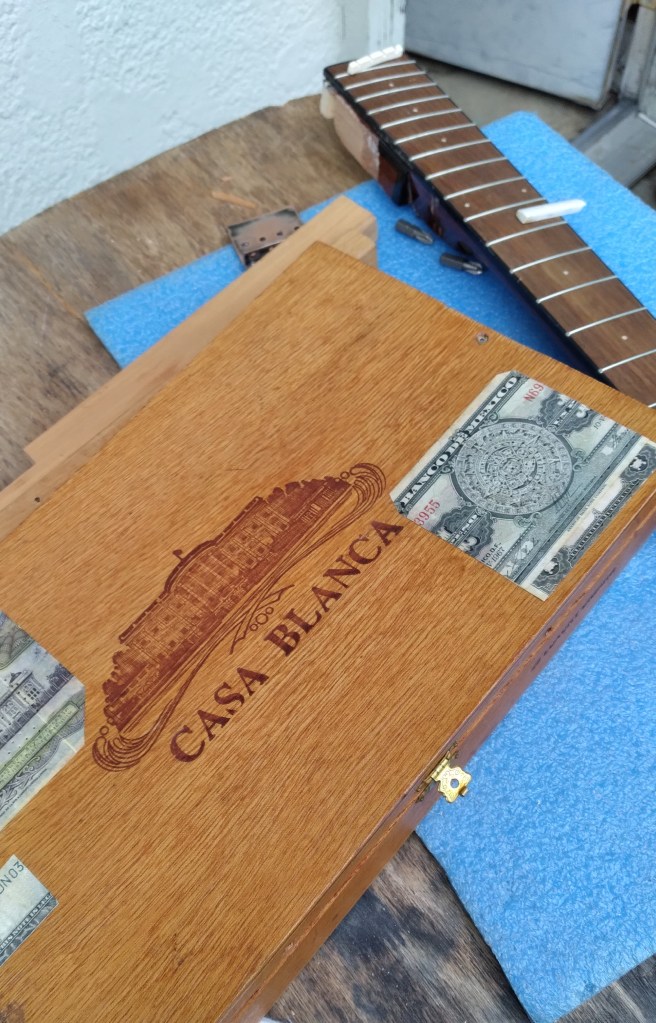

This is the box I used for my 2nd CB guitar failure and I’m recycling it here. It’s OK, at least I’m failing for different reasons. And getting valuable training.

I’ve got most of the parts I need except for, obviously, some way to tune it and adjust intonation.

Here’s the neck with the guitar nut removed, mounting wood and heel amputated, sides trimmed and lightly sanded.

So I have a nut and saddle and ball end holder, but no bridge or any way to tune it, not to mention intonate it.

I will need to cut the box to fit the new neck in depth at about the 14th fret. And also solidly attach this neck to an extention block reaching to the box end, screwed and glued tight, making it all rigid.

I need to research online for DIY headless guitar and bass tuners. They’ll have to fit off the neck/ extention block, beyond the end of the cigar box. How, I don’t know yet.

But grafting a recycled conventional headstock didn’t work that well on failure #2, along with me trying to build the neck, fretboard and nut.

So I need to go full headless and figure a tuning and intonation method to build. [See below- or maybe not.] Research needed.

[Postscript: Ain’t the Web something, this blog post has only been published for two hours. I do a Duck Duck Go web search for DIY headless tuners for ideas, and there is a link to my above post (see below), by about only the 3rd result page. With only 2 views, probably both from me. Wow, web crawler index software is lightening fast and more numerous than readers.]

I saw some good ideas for DIY headless tuners but now I’m leaning toward hacking the headstock off a defunct uke I have, then grafting it onto the bridge end of the cigar box. Here’s an example from talkbass.com, the social media site for bassists and bass guitar builders.

Looks a bit bass-akward and of course with this setup I won’t be able to set it down on the bottom. But it would require the least fabrication and, of course, zero cost. The tuners attached to the butt was one part of my 1st project failure that did work, weird as it looked.

Unless noted, all text and images by todgermanica.com.