I’m to the point on my cigar box, 4-string guitar/bass thing where I have to devise some way to tune the strings.

I’ve cut a plank of heavy reinforcement hardwood to fit in the bottom of the Casa Blanca cigar box. To which I will very firmly fasten my recycled Fender, acoustic/electric, 6-string guitar neck.

Right now I can close the box top but the new reinforcement plank is standing 1/4 inch too tall which makes the top bulge. Need to remove some material to make it fit.

I also want to cut off these two pieces of wood holding the neck a fraction of an inch too short, I’d like to see more of the 13th fret.

I see a plethora of holes in the box and the neck and I’ve got a good mind to fill them all in using the old toothpicks and glue weird trick, for strength. And the ability to drill anywhere when mounting it all up.

Now I need to find another, narrower, hardwood plank to firmly attach to the base reinforcement plank as an extension of the neck. This board will go out box end through the notch.

I used this ukulele headstock and machine heads for a previous failed box guitar. Giving up that idea for this attempt and I’m saving it for some future project.

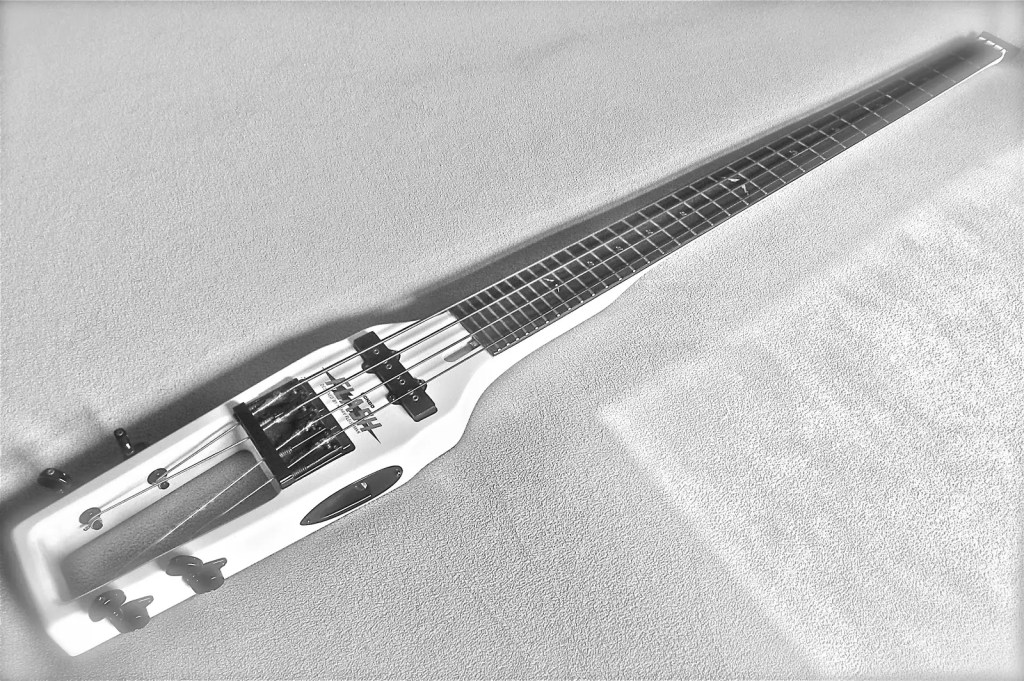

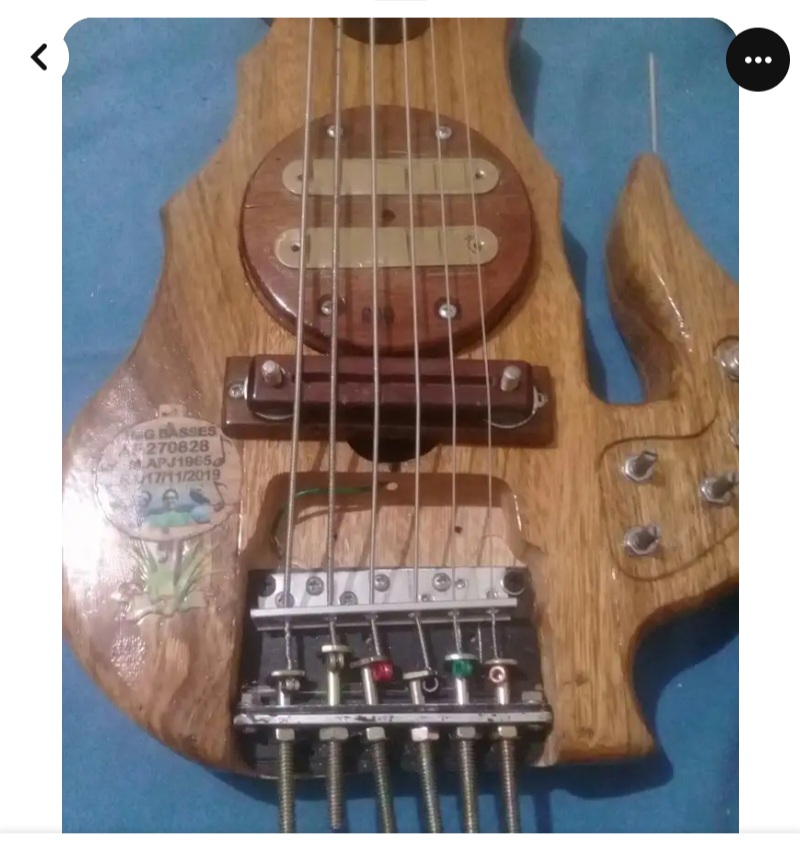

I’ll try to make my own, headless tuning system. Here are some examples from the web of how other CB guitar luthiers have whipped up homegrown tuning systems.

Image via talkbass.com.

From what I’m reading, headless in-line guitar string tuners have some advantages over conventional rotating machine heads so I’d like to see if I can devise some workable system to try it out.

I’ll be checking my shrinking woodpile for a sturdy hardwood tailpiece to butt up to the neck inside the box then run past the box end, which I’ll fasten to the hardwood reinforcing base plank.

I can attach whatever jury-rig tuning system I can come up with to the extension plank sticking out to the left here, when I build it. So for me it is stick searching. And heavy cogitation on making a tuning system.

Unless noted, all text and images by todgermanica.com.